Many deburring applications are possible with the flexible robotic cells

Multidimensional processing of workpieces with robotic cells by gKteso

Making numerous applications possible is the industryÔÇÖs requirement to mechanical engineering companies like gKteso. With its robotic cells, the company provides a technology solution that meets and exceeds the requirements of this trend. Background: During mechanical processes such as milling, punching or turning, most of the time burrs occur at the edges, due to material displacement. These are removed, for example, with our flexible DS integrated robotic cell, with which the edges are ground, brushed and/or milled. These systems are also suitable for minor milling and drilling works.

Applications for the automotive industry

The variety of workpieces processed for the automotive industry with the gKteso deburring robot ranges from exterior mirrors to structural components and crash components. Components for the latest generation of electric cars are also finished on our system. A wide variety of deburring processes can be used here.

Many applications and components

The value chain for the finished product is very long, especially for suppliers to automotive and commercial vehicle manufacturers. Components that were initially cast, turned, milled or machined using other metal-cutting manufacturing processes are given perfect edges without burrs in the deburring cells. Thanks to the multi-axis capability of our special robot, even highly complex components such as cylinder heads, hydraulic blocks and pump housings can be cleanly deburred. The precision of the deburring process supports the quality demands of the supplier industry and also increases the efficiency of the production processes.

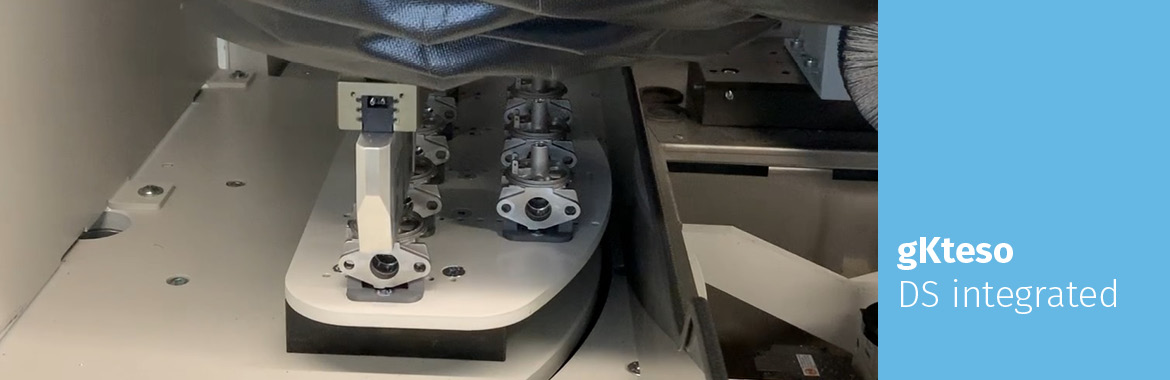

Robot cell DS integrated

Burrs at the edges of workpieces increasingly make the de-burring process an essential step in production, as for the industry it is ever more important to produce burr-free workpieces. Hereby, the potential applications are versatile and contemporary. The automated, closed deburring cells are supplied as flexible stand-alone system or as a component for production lines. With regard to the various applications, there is the option to choose either a workpiece- guided or a tool-guided system. Both procedures provide the same surface quality after processing.

Shorter cycle times in workpiece-guided de-burring

The difference is that in tool-guided deburring, the robot feeds the component to the machining stations. If different operations are to be performed, such as deburring, drilling or brushing on one workpiece, then it is advisable to move the component past different spindles. The cycle times are shorter than with tool-guided deburring, where the workpiece is clamped in a fixture and machined with the tools. Do you have any questions about your applications, deburring and the deburring cells from gKteso? Then give us a call or write us.

Download Datasheets

Download Datasheets