Automatic Deburring Speeds Up Industrial Processes:

From now on, deburr like a robot!

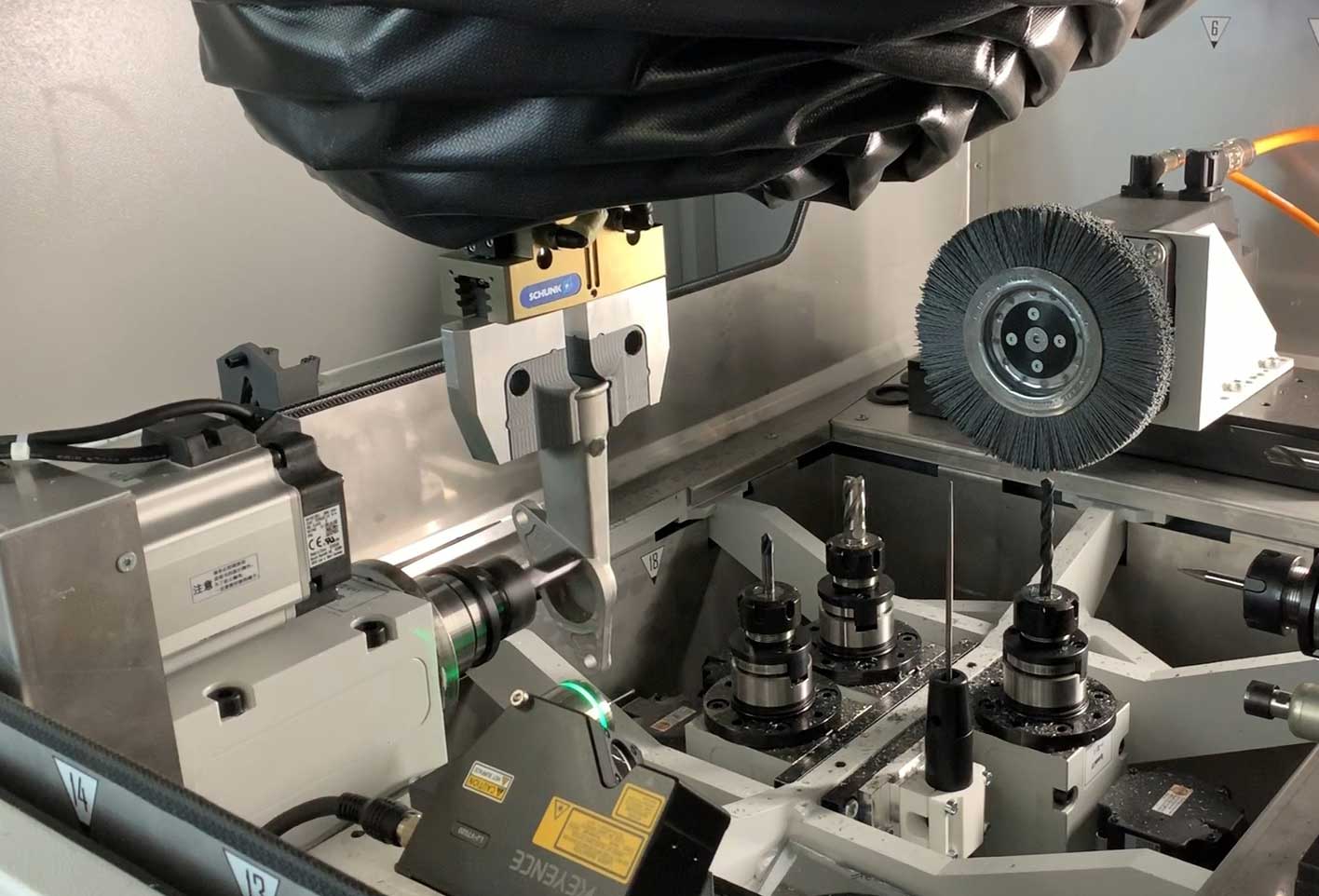

Different mechanical developments, such as cutting, punching or milling, create unevennesses, so-called burrs, in the material to be processes, which can result in a lower quality end product. It is therefore crucial to compensate for this fraying. Deburring, such as with a robot, with machines from gKteso always ensures a clean and quick result thanks to freely-moving axes.

Given the ever-advancing technological achievements, it is imperative for the various industries, such as the automotive and aerospace industries, to implement the deburring process with increased quality and also quantity as cost-effectively as possible in order to remain competitive on the market. The deburring from gKteso is particularly advanced here. The machines, also called deburring robots, relieve you of the manual fine grinding of various starting materials. They deburr various materials, such as steel or aluminum, automatically through…

- Grinding

- Brushing

- Polishing.

Automatic Deburring: Surface Finishing at the Highest Level

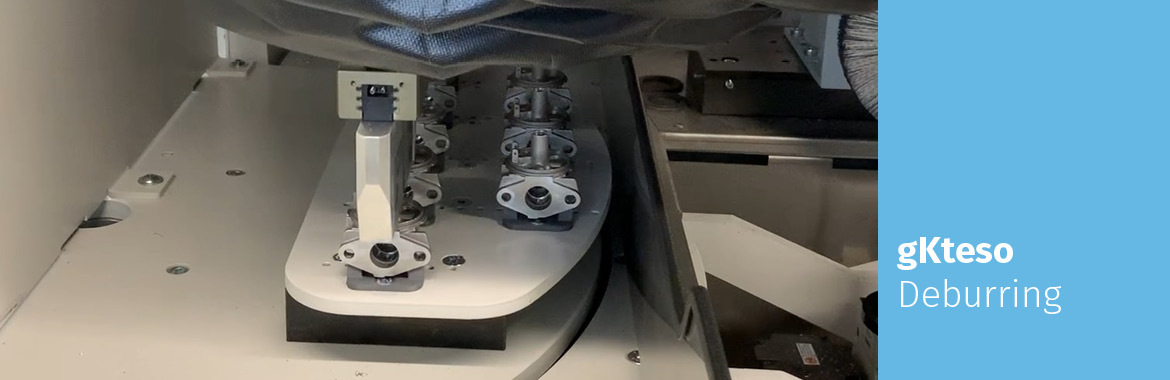

The complex deburring technology of our systems makes it possible to easily deburr even undefined and hard-to-reach roughnesses of multi-dimensional workpieces. The automatic deburring with the high-performance systems from gKteso ensures excellent results, which exceed the highest standards. All corners and edges of the material are freed of splinters or unevennesses caused by machining. This ensures the smooth further processing of the respective goods.

Complex Work Processes on a Powerful Machine

If you are considering automating deburring processes in order to minimize the duration and the costs of this work step, gKteso has developed two solutions for you: the entry-level model Deburring System base and the Deburring System integrated model. Both versions are ideal stand-alone systems, but can be integrated into the system of existing production lines just as easily. Several applications are even possible with these high-quality deburring machines: Light milling and boring work can be carried out on the workpiece. The resulting forms are then automatically smoothed as with a multi-axis robot articulated arm. Our robot cells work with the utmost precision in the process – accurate up to 0.1 millimeters! A feat that can hardly be achieved with manual processing in an economically efficient manner. Deburring with a robot from gKteso streamlines your production and increases the quality of the deburring.

If you require additional information about the deburring technology from gKteso, then simply get in touch with us at the telephone number +49 8234 / 966 38 41 or by e-mail: info@gkteso.de. Our experience consulting service will be happy to take the time to answer your questions in detail.

Download Datasheets

Download Datasheets