Deburring System DS base

Buy the entry model of gKteso

• High efficiency

• Multi-axis processing of complex workpieces

• Simple operation of the deburring systems

DS base deburring system – buy the entry-level model from gKteso

Automatic deburring, brushing, and testing

With DS base, the deburring system from gKteso, milled parts, die cast parts, sheet metal bending parts and also plastic components can be deburred, reamed, drilled out, rubbed, brushed and, if required, also inspected afterwards, so that 100% quality is guaranteed. Due to the flexible modular design, different components and different deburring or finishing processes can be applied.

Quality improvement through robotic deburring

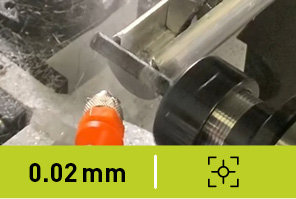

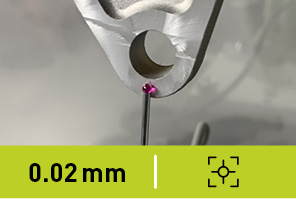

With the DS base, the edges are deburred cleanly, as with a CNC milling machine. Other finishing steps such as threads, fits, small re-mills or roundings can also be carried out with positional accuracy and, of course, automatically, as with a robot, always with the same reproducibility. Even final inspections or the marking of components can be integrated.

Advantages

- Universally expandable

- Repeatability 0.05mm

- Fast amortization

- Flexibilization of production

- Reduction of costs

Do you have questions about the technology solutions from gKteso for the die cast industry for machining die cast parts? Then call us or write to us.

28 years of experience

Specialists for machining complex workpieces

Sophisticated modular system

Learn more about our products!

We look forward to your inquiry!

Technical data:

| Workspace |

500 mm x 500 mm x 300 mm

|

| Total size |

1300 mm x 1800 mm x 2500 mm

|

| Maximum speed |

1 m/s

|

| Repeatability |

0.05 mm

|

| Web accuracy |

0.1 mm

|

| Workstations |

up to 16 |

Buy the entry-level model from gKteso for automatic deburring

DS base is the entry-level model in automatic deburring technology. The deburring cell is suitable for many industries. The deburring system is particularly appreciated and ordered by companies from the aerospace industry as well as the automotive and supplier industry. The variety of workpieces processed for the automotive industry with a deburring cell from gKteso ranges from exterior mirrors to structural components and crash components.

Advantages

- CNC programmable

- Low chip-to-chip time

- Easy to integrate into existing lines

Data sheet

DS base

DS base 5-axis deburring cell for complex shapes and geometries

With its five axes, the DS base deburring cell works very precisely, is flexible and processes even the most complex geometries and shaped elements. In this case, the program is generated on a separate workstation with the aid of a CAD-CAM program, as with a CNC milling machine.

To increase flexibility even further, the DS base robot cell can be equipped with an additional rotary axis.

All machining operations are performed in a completely enclosed workspace to meet even the highest safety requirements.