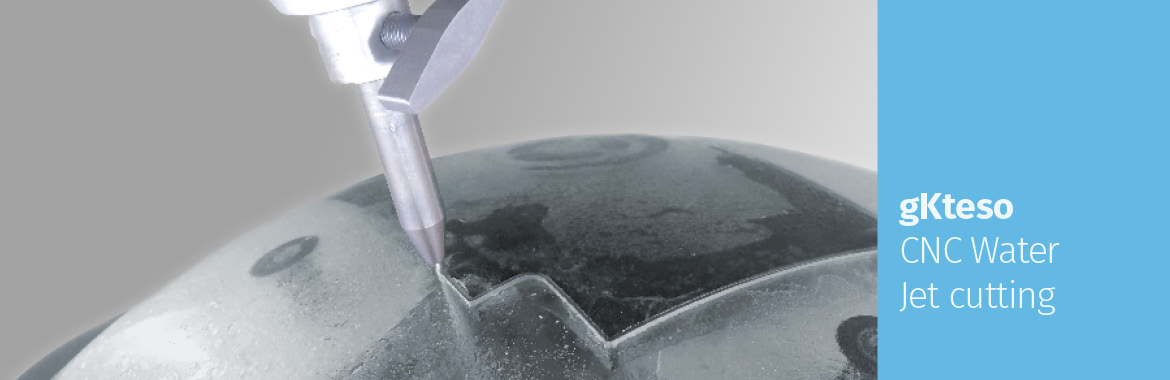

Water jet systems operate entirely to plan when they are sent computer-based data about the workpiece

CNC water jet cutting – from NC to modern computer-based applications

The abbreviation NC stands for numerical control. This designates a device to control machines such as NC water jet cutting. NC water jet cutting does not involve a computer for storing the data. NC programs work with simple binary codes, for example using perforated cards or strips. The development of computer technology turned NC into the more familiar CNC or computerised numerical control.

CNC water jet cutting makes it possible to mass-produce workpieces rationally. The axes and workpieces move on the basis of precisely defined parameters. The cutting speed can be significantly increased for low material thicknesses. However, CNC water jet cutting using conventional systems does mean significant angle errors on the cutting edge and groove formation if high cutting speeds are used. CNC water jet cutting using systems from gKteso means water jet cutting using completely new technology since the 5 D system controller immediately corrects angle errors. The system automatically calculates the perfect position of the cutting head without any intervention from the machine operator and implements its calculations during the cutting process.

Interpolation of the axes within milliseconds

CNC water jet cutting means high feed and cutting speeds even when machining thick materials with very low tolerances. The CNC machine tool is controlled by an integral computer. This uses sensors to record all positions, angles and actual states and then has a geometry program and an interpolation program to calculate the coordinates required for CNC water jet cutting. The desired status identified by these programs is used to control the operations of the machine elements. The interpolation takes place within milliseconds which means that precision is a given even at high speeds and for complicated workpieces. CNC water jet cutting is subdivided into categories depending on the number of axes which can be interpolated simultaneously. gKteso controls CNC water jet cutting using CNC systems manufactured by Bosch Rexroth, taking advantage of the long experience of Bosch as a leading manufacturer of electronic controllers and regulators.

Do you have a job which could be one for CNC water jet cutting? Then contact us. We will be delighted to advise you – for small, medium and large production volumes. Write to us at info@gkteso.de.

Download Datasheets

Download Datasheets