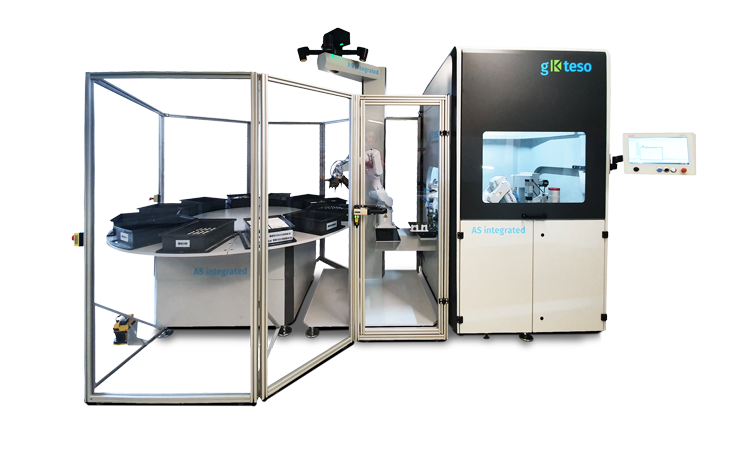

AS integrated

Machines for automatic assembly

• Universal

• Expandable (modular system)

• Also for small quantities

Each shift a different component

gKteso opens up completely new possibilities for cost reduction

A feeder robot is mounted in the center of the flexible AS integrated assembling system, which feeds the various individual parts, often prepared in bulk in product carriers on the turntable, to the compact assembly cell with camera support. This allows for quick and efficient changeovers for handling different tasks every day. For example, different assemblies can also be mounted during the day and at night. Of course, even a variant assembly can always be mounted according to requirements. If required, this is then easily scalable as demand increases, which offers a huge advantage.

Production processes change

The AS integrated assembly cell from gKteso changes with demand. Changing production processes are becoming more and more common, and companies are therefore forced to be much more adaptable. With the flexible production systems such as the assembling system (AS) integrated, you are one step ahead of your competition. Rapid replacement of processes is just as possible here as rapid changeover to other variants.

Advantages

- Quick change to other variants

- Processes can be easily added or changed

- Quickly converted

- Flexibilization of production

- Reduction of costs

Do you have questions about the technology solutions from gKteso for the die cast industry for machining die cast parts? Then call us or write to us.

28 years of experience

Specialists for machining complex workpieces

Sophisticated modular system

Learn more about our products!

We look forward to your inquiry!

Technical data:

| Component weight |

Up to 2 kg

|

| Goods carrier |

Up to 16

|

| Maximum speed |

4 m/s

|

| Max. number of parts |

Up to 48 individual components

|

Customer-specific processes can be integrated

The AS integrated is already available as standard with a range of processes such as gluing, screwing, greasing, press-fitting, inserting, and testing. gKteso already offers modules for this purpose. Thanks to the modular system, customer-specific processes or devices can also be integrated very easily. This makes it possible to take over and automate the customer-specific expertise that has been built up over many years of product-specific production.

Advantages

- Standard processes available

- Customer-specific production processes can be integrated

- Users can use production expertise

Fit for the future AS integrated

The majority of costs in assembly are caused by logistics. With the AS integrated automatic assembly cell, these can also remain low in the future because the components are not only made available to the actual assembly center by the logistics robot, but this is already prepared so that automatic transport systems can also be connected. This allows for reduced staffing throughout the chain.