Waterjet Cutting System WCS base

Efficient cutting of serial parts with waterjet

• High output

• 5 axis cutting implemented

• Precise cutting edges

Waterjet cutting with high 3D path accuracy

Compact waterjet system for high output

Designed for a small footprint, the cell with completely enclosed workspace meets the highest safety requirements and allows easy access for component changes. The optimum high-pressure pump is used depending on the material to be cut. Up to 6000 bar if required. Depending on the material, additional abrasive is added to the cutting jet. In combination with the 6-axis mechanics designed for rigidity, this results in very high and reproducible path accuracy.

Waterjet cutting machine for 3D parts

If you are looking for the right waterjet cutting machine for your projects, gKteso GmbH is your competent partner. For precise waterjet cutting, we offer high-quality machines that you really should take a closer look at. Numerous companies from different industrial sectors trust a waterjet cutting system from our portfolio. The five-axis cutting systems WCS base and WCS integrated (WCS stands for Waterjet Cutting System) that we offer can be perfectly integrated into production lines and enable the fastest machining processes thanks to their efficient and reliable technology. Simply send us your component drawing and we will check the feasibility.

Advantages

- Compact layout

- Repeatability 0.05mm

- High productivity

- Flexibilization of production

- Reduction of costs

Do you have questions about the technology solutions from gKteso for the die cast industry for machining die cast parts? Then call us or write to us.

28 years of experience

Specialists for machining complex workpieces

Sophisticated modular system

Learn more about our products!

We look forward to your inquiry!

Technical data:

| Workspace |

500 mm x 500 mm x 200 mm

|

| Total size |

1300 mm x 2300 mm x 2500 mm

|

| Maximum speed |

1 m/s

|

| Repeatability |

0.05 mm

|

| Web accuracy |

0.1 mm

|

| Working pressure |

up to 6000 bar |

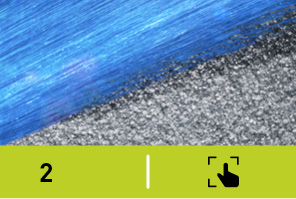

Ideal for difficult materials

Waterjet cutting with pure water is used in particular for processing plastics, sealing materials, rock wool, foams, and rubber. For harder materials, very fine quartz sand is added to the water as an abrasive. Natural stone, steel, aluminum, carbon, carbon fiber materials, numerous types of glass, non-ferrous and non-ferrous metals, hard plastics and composites, ceramics, and metal castings are precisely separated with the mixture. Another advantage is that many very different materials can be cut – such as metal with rubber, aluminum foil with insulation material, composites, and mixed plastics.

Advantages

- Cutting of elastic materials

- Cutting of carbon

- Cutting of composite materials

Data sheet

WCS base

Cost benefits of water jet cutting through quality and speed

The cost benefits of water jet cutting are mainly due to the fact that it makes it possible to create a precise, reproducible and easily automated process. Tool wear and the retooling times this incurs are significantly reduced compared to conventional cutting processes. This means no loss of quality caused by tool wear. Workpieces cut with a water jet have a precise finish and can be used without any further work – yet another cost benefit of water jet cutting.