Automated deburring is all about your workpiece.

CNC deburring and post-processing of aluminum, steel and zinc die-casting – call now

Automated deburring of aluminum, steel and zinc die-casting – precise, quick and in up to 8 axes

gKteso represents efficient solutions. We use precisely contoured processes to create smart and resource-protecting procedures for post-processing of aluminum – on request also partially or fully automated.

We build deburring cells and grinding systems for many different applications and materials. Therefore, our machines can be integrated individually. Talk to us: we have the right system for you!

You may currently visit us at EMO in Hanover from 18 – 23 September 2017, hall 11, stand A15 , where we will inform you about CNC-based deburring and post-processing of aluminum, steel casting and zinc die-casting.

Deburs nearly any material

Economically efficient deburring

High precision,

high degrees of freedom

Processing in up to 8 axes

Diversity of workpieces, processing of variations

Are you under time pressure? Automation is your solution – Ideal for medium-sized and large series.

DS base and DS integrated are the innovative deburring cells of gKteso. Even the entry model DS base can be easily automated. DS integrated offers three options for main-time-parallel equipment: a change table, a round table and the robot-supported supply of parts.

Lower your unit costs very simply! Talk to us – we have experience:

Innovative 3D-machine increases throughput

Faster with consistently high quality

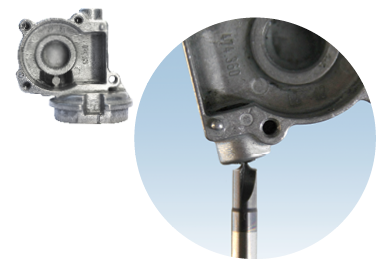

Complete several work steps in a single cell: workpiece-controlled processing picks up speed. The multi-dimensionally movable arm of the machine grasps the workpiece and guides it to the individual processing steps. This way, aluminum parts can be speedily deburred, drilled, cut and brushed – everything in a single pass and without any elaborate re-clamping or transport paths.

Anyone can join components

– we build machines

Quality and precision with best track and repeat accuracy – this is our target. Therefore, we build machines that are thought-through in all details. All parts are coordinated with each other and optimized to permit a quick and precise sequence of motions.