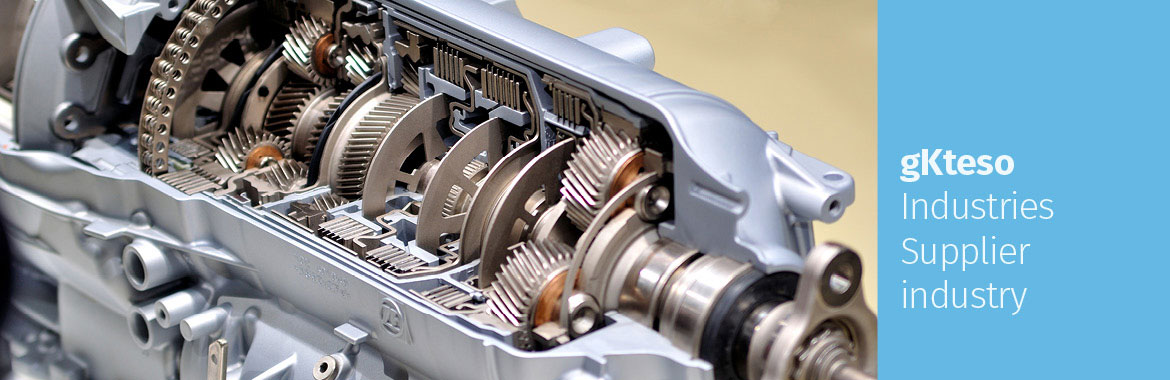

Supplier industry requires efficient production

Cutting technology by gKteso ensures sharp edges

The supplier industry brings the most innovations onto the market, taking on ever more services in the production and development of motor vehicles. Latest figures reflect the following: About 78 percent of the entire value chains in the automotive industry are performed by the suppliers – with increasing tendency. Hereby, the industry is under extremely high pressure. This is driven by an increasingly tough global competition, cost and price pressure, higher material costs up to a more restrictive behavior of banks and investors. One of the significant consequences is the consolidation of the production processes.

Production with efficiency

Lean production and efficient, automated processing methods are in high demand, more than ever. gKteso has recognized this trend in the supplier industry at an early stage and has been developing cutting technology for up-to-date processing of modern materials. Cars are fitted with numerous workpieces that need cutting without interrupting or slowing down the production flow. The machines and systems are based on a sophisticated modular principle. Following prior processing tests, the technology is therefore adapted only on a small scale, if necessary. The automated cutting technologies in the powerful waterjet-cutting systems or multi-axle laser cutting systems by gKteso cut metals, carbon or composite plastics.

Cutting technology for the supplier industry

From hydraulic blocks, trimmed mirrors, armatures up to thermal and acoustic insulations for engines, everything that requires multidimensional, custom-fit and high-quality separation is processed in systems by gKteso. The high quality claim is documented by exemplary systems as well as certifications, for example DIN ISO 9001.

Custom-fit cuts for perfect structures

Either with pure water or the addition of sand – the cuts of waterjet cutting systems by gKteso are clean and particularly suitable for multidimensional cutting of functional components. As there is no heat generated during the cutting process, deformations are no subject to worry about. Laser cutting systems are applied where demanding or possibly three-dimensional outlines require precise and fast processing. Cutting technology by gKteso also masters areas of limited access or cuts precisely when powerless processing is required.

Best surfaces for the supplier industry

Precise cuts support the quality demand of the supplier industry making production processes particularly efficient. You have questions in regards to cutting technology by gKteso applied in productions of the supplier industry? Then give us a call or write us.

Download Datasheets

Download Datasheets