Grinding System GS base offers highest form of automation

Grinding machine by gKteso achieves more than just grinding

Grinding with highest automation and precision is provided with the entry-level model Grinding System GS base by gKteso. The grinding machine is fitted with a measuring control that checks and corrects the grinding wheel wear in regular intervals. Special feature of a grinding machine by gKteso: GS base has a high integration capability in production lines. Whoever wishes to process many parts will have financial benefits resulting from the fact that cost saving in automated sanding is particularly high in large quantities when compared with manual processing. This way production costs can be reduced while production processes will be more efficient.

Grinding System makes post-processing particularly convenient

Post-processing of metals is particularly convenient with this 6-axis system, as it is especially designed for automated sanding of components. Particularly in the supplier industry, the Grinding System GS base combined with its sanding wheels permits fast and process-reliable post-processing of components made of steel, stainless steel or aluminum. The powerful grinding machine by gKteso is found in production halls of many industries. Companies in steel construction and facade engineering use it for efficient sanding and surface finishing of welding seams after resistance welding. The customers receive products with appealing optics.

Grinding machine removes gates and scaling

Equipped with appropriate sanding wheels, even hard materials can be automatically processed at high dimensional and shape accuracy. In foundries, grinding machines by gKteso separate parts of different shapes, remove gates, scaling and rust film from surfaces. In medical technology, automotive industry or other industry branches, grinding machines by gKteso provide the desired surface finish at the end of a production chain. Whether in line or in stand-alone operation, the Grinding System by gKteso ensures a brilliant cut in production halls of midsize and large companies.

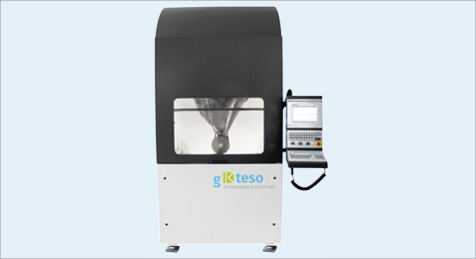

Grinding machine by gKteso with Bosch control

GS base is equipped with a Bosch-Rexroth control (DIN-programming). Its work space measures 400 mm x 400 mm x 200 mm, it is completely closed and therefore even meets increased safety requirements. The maximum velocity is 1 m/s, the repetition accuracy is 0.05 mm and the path accuracy is 0.1 mm. Further advantage of GS base is its high rigidity. High-performance spindles for standard grinding discs (230 mm) have been fitted in the machine. Besides, the system is already prepared for connection with a suction device for ground material as well as further automations.

Highest precision in sanding with GS base

GS base by gKteso not only provides highest precision and reproducibility. Also convincing is the cost saving of automated sanding when compared to manual processing procedures. In developing GS base, wide-ranging knowhow in sanding various materials has been an influencing factor. This is recognizable through the fact that the grinding processes and techniques are optimally adapted to the processing procedures. You have questions in regards to grinding and the entry-level model GS base by gKteso? Then give us a call or write us.

Download Datasheets

Download Datasheets