Conicity is not necessarily given in water jet cutting!

Mobile cutting heads automatically compensate for angle errors

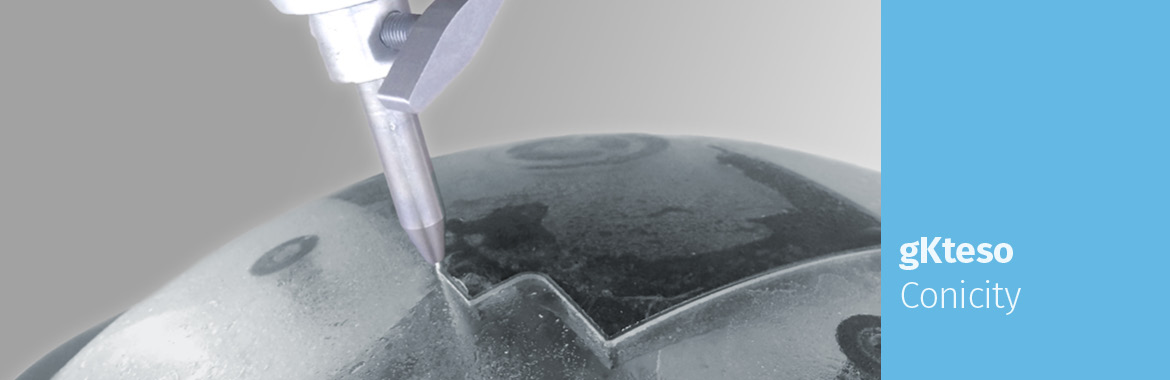

The problem of conicity in water jet cutting is not a new one. The water jet does not have a linear form as shown by the cut edges of the workpiece which generally have angle errors when conventional water jet systems are used. The cutting jet becomes narrower from top to bottom during cutting, particularly at high velocity, and this leads to the conicity of the edge. If a workpiece is to be machined further anyway or if the quality of the cut edge is not a vital parameter, angle errors can be ignored. However, as soon as precision edges or absolutely cylindrical bore holes are required, conicity must be compensated. The lowest possible tolerances have previously come at the expense of speed. Water jet cutting has also often been rejected simply for reasons of conicity and the company has used a laser or mill to cut its workpieces.

Improved software and a moving cutting head deliver high quality

Conicity should not be a reason to rule out the use of water jet cutting. After all, it is an ideal process for many applications since it enables cuts to be made with great precision and speed whilst also not subjecting the workpiece to thermal stresses. Almost any material is suitable for the process, up to a thickness of around 150 mm. Our modern systems now make it possible to compensate for conicity during the cutting process without losing any time at all. Two things make the difference in this respect – on the one hand a moving cutting head on a finely adjustable rotary joint and on the other a software package which is able to control and analyse the complete cutting process and adjust the cutting head continuously to achieve precision edges. And it is able to do so for any shape and any material – a quite superlative performance. The result of this process includes precision edges without any negative conicity, and with no loss of time or additional procedures. Angle errors in water jet cutting have therefore finally been consigned to the past.

Take a look for yourself at the quality of our systems. Getting contact with us, tell us about your project and allow us to machine a specimen workpiece using our water jet system. You will be delighted with the results. Contact us now at info@gkteso.de.

Download Datasheets

Download Datasheets