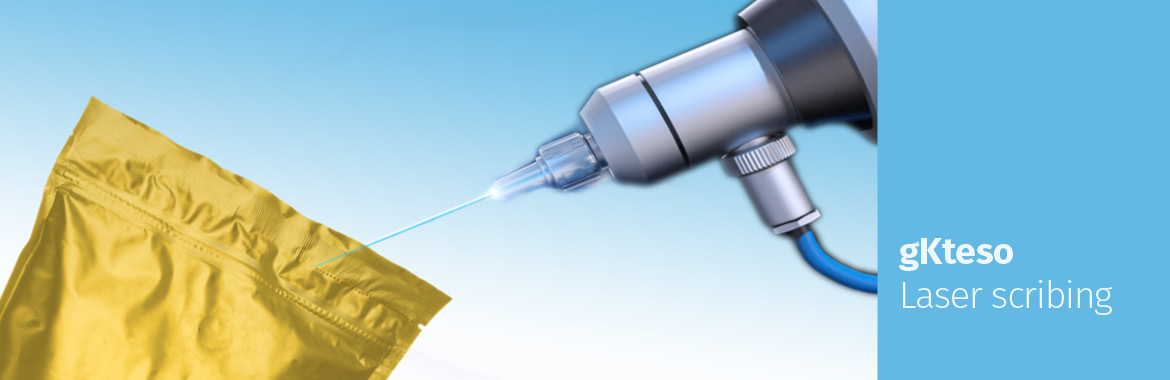

Laser scribing makes it possible to weaken individual layers on a targeted basis to prepare them for controlled use

Everybody has been annoyed by some form of packaging that cannot be opened despite having a tearing thread. Laser scribing puts an end to this problem

Laser scribing enables packaging to be opened easily without requiring any great force and precisely at the required point. These “easy opening” features do not adversely affect the protective properties of the packaging which also retains its mechanical functions. Product designers also welcome laser scribing for sales packaging because it enables the packaging to be scribed from the inside before being filled with the food so that the opening point on the outside can be printed perfectly. Diagonal laser scribing or free-form laser scribing is another possibility, thus making creative opening points, the removal of packaging parts, the division of sales packaging with multiple components or the clean separation of packaging possible. Laser scribing for packaging is also used in the convenience food sector to prepare bags for the microwave or heating in food steamers. The opening points do not form at the scribed areas until sufficient pressure has built up in the bag from the steam generated by the heated food. This means that the product remains fresh during its shelf life whilst also allowing the cooking process to be controlled by these smart perforations.

Creative openings are easy to achieve – straight, rounded or however you wish

All packaging materials are suitable for laser scribing, whether that means innovative foil or green packaging made of bamboo, cardboard or paper. Existing production can also be transferred from punching, perforation or stamping to laser without having to change the material. Easy opening straight perforations can also be used on laminates or mono-foils. Certain forms such as rounded tear-off corners or arcs can also be achieved very easily on foil material. The material can be scribed in its winding direction, perpendicular to it or as required to produce the easy opening solution. Laser scribing can be integrated both in the finishing process and in the actual packaging system. The tiresome tearing thread which can often not be found or released and in some cases does not even tear the packaging can finally be consigned to the past.

Could easy opening be a solution for your packaging? Then talk to us – would be delighted to advise you. Send a mail to info@gkteso.de.

Download Datasheets

Download Datasheets