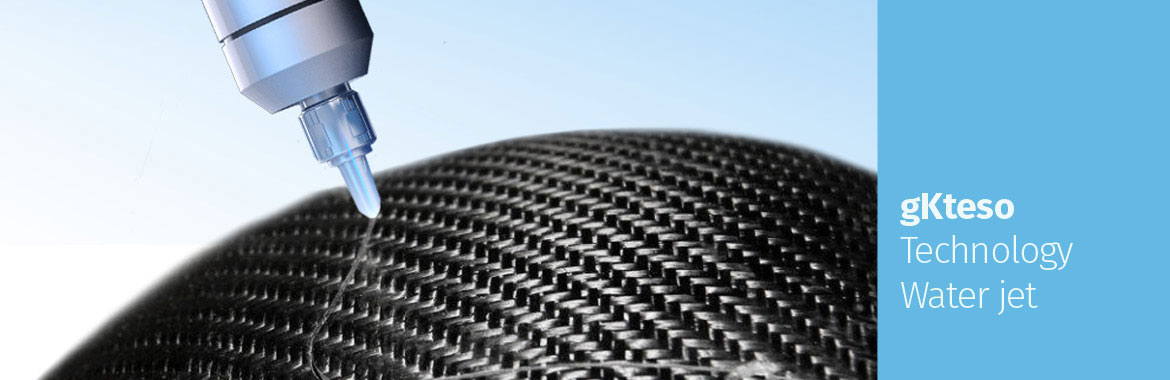

Waterjet cutting with powerful technology

Waterjet cutting systems provide perfect cutting processes

In waterjet cutting, various materials are precisely separated by a high-pressure waterjet. Hereby, the multi-axial features of waterjet cutting systems by gKteso provide multidimensional cuts, due to their modern technology. In the operating process, a water pressure of up to 6000 bar and outlet flow rates of up to 1000 m/s are generated. This technology makes it possible to cut even plastics or hardened steel by using water. There is no heat arising during the cutting process and therefore no subject to worry about melting behavior.

Waterjet-cutting without heat

Depending on the requirement, waterjet cutting systems with extensive, modern technology are equipped with corresponding pumps, which again are different in their capacities. The noise generated during waterjet cutting, for example through the increase of the water level in the beam attenuator and in the immediate operating area, is strongly reduced by means of the closed system. This technology lowers the noise emission significantly.

High pressure and finest sand

The abrasive material, finest quartz sand, which can be applied under high pressure in waterjet cutting, is dosed by CNC-control and, combined with air as the carrier element, conveyed to the cutter head. The feed rates in the cutting process depend on parameters such as type and thickness of the material, pump capacity (volume flow and pressure) as well as the nozzle combination (water nozzle (0,25 mm or 0,35 mm) and focusing tube (0,8 mm to 1 mm)).

Modern technology for the cutting process

Waterjet cutting systems by gKteso consist of various components: Accumulator, high pressure piping, control by Bosch-Rexroth (DIN programming), pump „Streamline SL-V 50 Classic” by KMT and nozzle. The engine frame made of steel carries the machine’s axes. After the cutting process, the water jet, now highly energetic through the pressure applied, is retained by a water tank functioning as “beam attenuator”, and subsequently converted into heat. This requires a water tank with a sufficient water column in order to protect the system from overheating. Since the heating may have an effect on the material’s behavior, the systems provide CNC-corrections, meaning latest technology.

Pulsation-free cutting process

The high pressure pump Streamline ensures a pulsation-free high pressure waterjet. The feed flow in this technology amounts up to 15.2 liters per minute at a pressure of 3800 bar. The cutting water, which is mixed with particles and sand after the work process, can be separated by a sludge removal unit. Waterjet cutting systems by gKteso are equipped with CNC-controls by Bosch-Rexroth, permitting to interpolate all axes as well as to perform an adaptive feed rate reduction, depending on the cutting process. You have questions around waterjet cutting and the technology of waterjet cutting systems by gKteso? Then give us a call or write us.

Download Datasheets

Download Datasheets