Technology by gKteso makes laser cutting efficient

Laser cutting systems score with precision

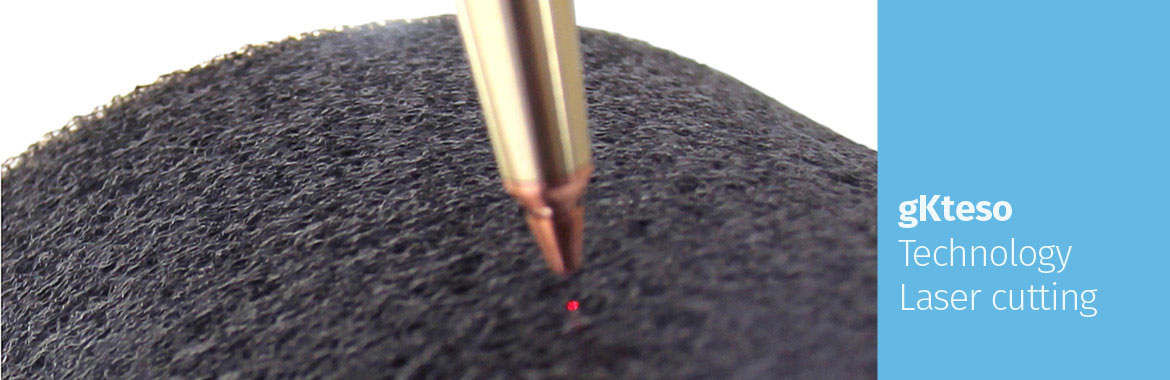

The technology of laser cutting included in laser cutting systems by gKteso, permits processing of even complex, three-dimensional outlines. The processing procedure is fast, precise and allows powerless as well as efficient cutting in areas of difficult access – regardless whether a high-performance laser or an optimally focusable fiber laser is used. The laser beam source, the laser beam guidance, the processing head as well as the cutting nozzle form the core of this technology. During laser cutting, the focusing optics bundle the laser beam, subsequently generating the intensity required for cutting. Laser cutting systems by gKteso facilitate the piercing process, avoiding back reflection or metal splashes in pulsating intervals.

Technology for various cutting tasks

Laser cutting copes with various cutting tasks. Laser cutting systems by gKteso even process complex workpieces, from cutting kerfs in semiconductor chips, accurate to the micrometer, up to steel sheets of a thickness of up to several millimeters. Also targeted drilling is possible, whereby the laser beam inserts finest to larger holes contact-free into metals, plastics, composite plastics, wood, paper or stones without material puncturing.

Laser cutting combines two work steps. At the beginning of the process, the laser beam is absorbed at the cutting front. Hereby, this technology carries in the required energy for cutting. In the second step, the cutting nozzle, concentrically arranged to the laser, provides the processing gas. This protects the focusing optics from vapors and splashes, pushing the removed material out of the kerf. In this work step, the laser cutting systems generate heat. In this technology, material deformations occurring at the cut kerfs cannot always be avoided. That is why it should be tested beforehand, whether the material tends to liquefy, vaporize or oxidize during cutting. Depending on the result, the type of laser cutting will be determined.

Laser cutting without tool costs

Essential advantages of laser cutting systems are omitted tool costs and therefore cost-effective, faster and more flexible production, as there is no tool change required. Post-processing of cutting edges won’t be necessary either with this contact-, vibration-free processing technology. Equally advantageous for numerous production processes is: Good reproducibility of the processing procedure, e.g., the possibility of full automation of laser cutting and integration into line productions. You have questions regarding laser cutting systems by gKteso and laser cutting? Then give us a call or write us.

Download Datasheets

Download Datasheets